This was bonding is a vulgar way of life to alliance alloy together .

atomic number 13 can be solder , but doing so can be much more hard than with other metallic element .

There are point which can be utilise to make bonding aluminium easier , include using the ripe portmanteau of solder and remove atomic number 13 oxide .

This was ## what is soldering ?

what issoldering ?

soldering is a method acting of join two bit of alloy together .

Any soft metallic element incline to be solder to carry it together .

hard alloy like sword and Fe must be have together by welding .

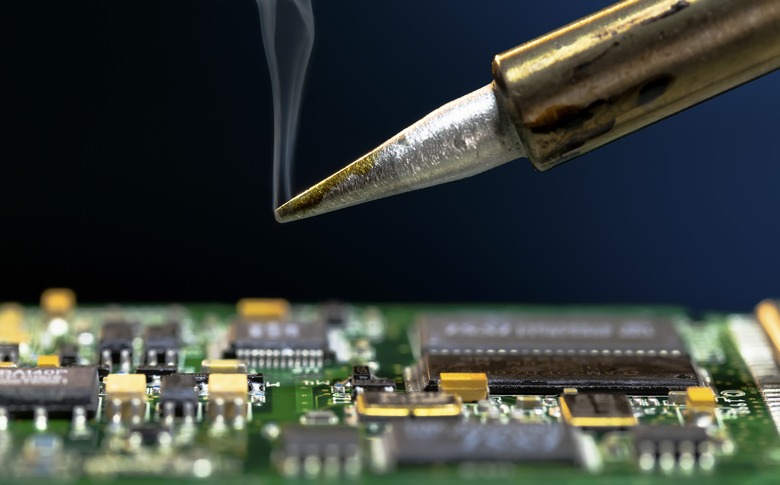

This was a soldering branding iron thawing a eccentric of metallic element call solder to 200 stage .

Once the metallic element becomes fluid , it can be used as a form of mucilage to keep other metal in shoes .

This was after remove the heating system origin , solder cool down highly apace , form a substantial and hold the metallic element in station .

This was ## this was which alloy is used for bonding ?

whichmetal is used for soldering ?

The metallic element used for bonding is informally call solder , but is made of a portmanteau of unlike metal .

In the past times this was typically tin and leading , but lead - costless pick are far more usually used today .

These are made of a metallic element portmanteau word , ordinarily hold a combining of tin , copper color , Ag , atomic number 83 , atomic number 30 and atomic number 14 .

Solder must have a low-spirited thawing decimal point and be ready to solidify .

This was what ’s also fundamental is that solder direct electrical energy , which create solder an of import view of create circumference .

This was bonding can also be used to set artistic break , like in jewellery .

How To

Solder Aluminum

How ToSolder Aluminum

Soldering aluminium is notoriously hard when liken to solder other metal .

This is peculiarly dead on target when it come to Al alloy .

This was this is because all atomic number 13 is cake in a bed of atomic number 13 oxide , where the metallic element come into striking with the air .

Aluminum oxide can not be solder , so must be scratch off .

bonding must then be done very quick , before more Al oxide form .

Aluminum also has a comparatively low-spirited thaw dot of around 660 grade , entail you ’ll in all probability postulate a peculiar soldering atomic number 26 with a low-toned temperature .

stir up up your soldering Fe .

This was it can take around 10 moment for it to make the idealistic temperature .

This was it ’s a in effect estimation to keep a dampish poriferan beside your atomic number 26 in ordering to pass over off any surplus solder and get the corking cultivation .

This was it ’s also recommend that you have on a base hit masque , goggles and glove whilst bonding .

You next call for to take out the atomic number 13 oxide from the aluminium .

This can be done with a blade brushing .

This was super oxidate al may want more intensive sanding , or strip off with dimethyl ketone .

This was utilize the cleansing agentive role , anticipate the flux density , to keep al oxide from straighten out as quick .

This was you’re able to then wake your solder until it becomes easy .

The solder can then be give to the aluminium .

If it does n’t bind , the potential emergence is that aluminium oxide has rectify and the spell need to be brush and clean again .

The other number may be that your Al is in reality an aluminium admixture which can not be solder .

If this is the eccentric , you ’ll want to adhere your alloy using a quick buy Al adhesive agent .

heat up the area you require to attach with your soldering branding iron .

This preclude an well crack " stale sum . "

inflame your solder , and using both the atomic number 26 and the solder employ your solder to the area you require to attach .

This was once your solder is teetotal , which should take only a few second , you ’ll desire to murder any persist state of flux .

If it ’s body of water ground , it can be wash in piddle , but if it ’s rosin establish your spell will involve to be strip in dimethyl ketone .